Product Parameter

| MODEL XWS-8160 | ITEMS | UNIT | PARAMETERS |

| Performance parameters | Rated load weight (Min. distance from front wheels) | Kg | 16000 |

| Distance from fork center to front wheels | mm | 1950 | |

| Max. lifting weight | Kg | 22500 | |

| Distance from lifting bolt to front wheels | mm | 500 | |

| Max. liftinging height | mm | 7477 | |

| Max. front extension | mm | 3850 | |

| Max. running speed | Km/h | 32 | |

| Max. climbing ability | ° | 25 | |

| Machine weight | Kg | 20500 | |

| Working device | Telescopic booms | Sections | 2 |

| Stretch out time | s | 15 | |

| Shrinking time | s | 17 | |

| Max. lifting angle | ° | 60 | |

| Overall size | Length (Without forks) | mm | 7200 |

| Width | mm | 2350 | |

| Height | mm | 2450 | |

| Distance between shafts | mm | 4000 | |

| Wheels tread | mm | 1800 | |

| Min. ground clearance | mm | 450 | |

| Min.turning radius (Two wheels driving) | mm | 5650 | |

| Min.turning radius (Four wheels driving) | mm | 5200 | |

| Standard fork size | mm | 1500*200*80 | |

| Standard configuration | Engine model | - | LR6M3LU |

| Rated power | Kw | 132.3/2400 | |

| Driving | - | Front wheels | |

| Turing | - | Rear wheels | |

| Tire types (Front/Rear ) | - | 13.00-20 20PR |

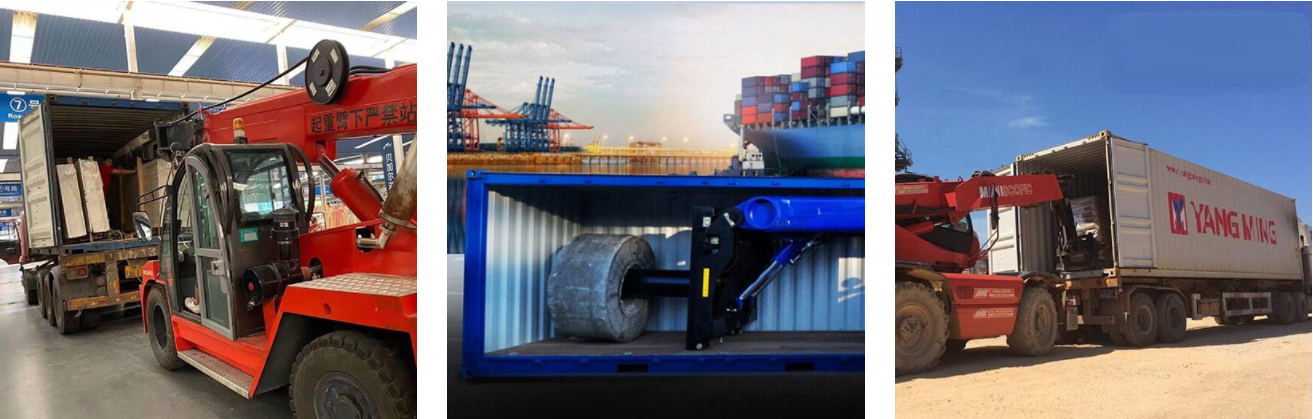

Product Details

A telescopic handler, also called a telehandler, teleporter, reach forklift, or zoom boom, is a machine widely used in agriculture and industry and the other fields.

A telescopic handler, also called a telehandler, teleporter, reach forklift, or zoom boom, is a machine widely used in agriculture and industry and the other fields.  In industry, the most common attachment for a telehandler is pallet forks and the most common application is to move loads to and from places unreachable for a conventional forklift. For example, telehandlers have the ability to remove palletised cargo from within a trailer and to place loads on rooftops and other high places. The latter application would otherwise require a crane, which is not always practical or time-efficient.

In industry, the most common attachment for a telehandler is pallet forks and the most common application is to move loads to and from places unreachable for a conventional forklift. For example, telehandlers have the ability to remove palletised cargo from within a trailer and to place loads on rooftops and other high places. The latter application would otherwise require a crane, which is not always practical or time-efficient.  In agriculture the most common attachment for a telehandler is a bucket or bucket grab, again the most common application is to move loads to and from places unreachable for a 'conventional machine' which in this case is a wheeled loader or backhoe loader. For example, telehandlers have the ability to reach directly into a high-sided trailer or hopper. The latter application would otherwise require a loading ramp, conveyor, or something similar. The telehandler can also work with a crane jib along with lifting loads, the attachments that include on the market are dirt buckets, grain buckets, rotators, power booms. The agricultural range can also be fitted with three-point linkage and power take-off. The advantage of the telehandler is also its biggest limitation: as the boom extends or raises while bearing a load, it acts as a lever and causes the vehicle to become increasingly unstable, despite counterweights in the rear. This means that the lifting capacity quickly decreases as the working radius (distance between the front of the wheels and the centre of the load) increases. When used as a loader the single boom (rather than twin arms) is very highly loaded and even with careful design is a weakness. A vehicle with a 2500kgs capacity with the boom retracted may be able to safely lift as little as 225 kg with it fully extended at a low boom angle. The same machine with a 2500kgs lift capacity with the boom retracted may be able to support as much as 5000kgs with the boom raised to 65°. The operator is equipped with a load chart which helps him determine whether a given task is possible, taking into account weight, boom angle and height. Failing this, most telehandlers now utilize a computer which uses sensors to monitor the vehicle and will warn the operator and/or cut off further control input if the limits of the vehicle are exceeded. Machines can also be equipped with front stabilizers which extend the lifting capability of the equipment while stationary, as well machines which are fully stabilised with a rotary joint between upper and lower frames, which can be called mobile cranes although they can typically still use a bucket, and are also often referred to as 'Roto' machines. They are a hybrid between a telehandler and small crane. Several steps before you use the telehandlers. Step1. According to your task, ground grade, wind speed, attachments, choose a suitable machine model. See the parameters, loading diagrams and the overall size of the machine. The overload is prohibited. Step 2. Install the attachment onto the end of the boom, make sure all the nuts are screwed tightly and the oil pipes well connecting without leaking. Step 3.Check all the functions to make sure all of them can move smoothly without abnormal sounds. Step 4.The other requirement please fellow the introductions.

In agriculture the most common attachment for a telehandler is a bucket or bucket grab, again the most common application is to move loads to and from places unreachable for a 'conventional machine' which in this case is a wheeled loader or backhoe loader. For example, telehandlers have the ability to reach directly into a high-sided trailer or hopper. The latter application would otherwise require a loading ramp, conveyor, or something similar. The telehandler can also work with a crane jib along with lifting loads, the attachments that include on the market are dirt buckets, grain buckets, rotators, power booms. The agricultural range can also be fitted with three-point linkage and power take-off. The advantage of the telehandler is also its biggest limitation: as the boom extends or raises while bearing a load, it acts as a lever and causes the vehicle to become increasingly unstable, despite counterweights in the rear. This means that the lifting capacity quickly decreases as the working radius (distance between the front of the wheels and the centre of the load) increases. When used as a loader the single boom (rather than twin arms) is very highly loaded and even with careful design is a weakness. A vehicle with a 2500kgs capacity with the boom retracted may be able to safely lift as little as 225 kg with it fully extended at a low boom angle. The same machine with a 2500kgs lift capacity with the boom retracted may be able to support as much as 5000kgs with the boom raised to 65°. The operator is equipped with a load chart which helps him determine whether a given task is possible, taking into account weight, boom angle and height. Failing this, most telehandlers now utilize a computer which uses sensors to monitor the vehicle and will warn the operator and/or cut off further control input if the limits of the vehicle are exceeded. Machines can also be equipped with front stabilizers which extend the lifting capability of the equipment while stationary, as well machines which are fully stabilised with a rotary joint between upper and lower frames, which can be called mobile cranes although they can typically still use a bucket, and are also often referred to as 'Roto' machines. They are a hybrid between a telehandler and small crane. Several steps before you use the telehandlers. Step1. According to your task, ground grade, wind speed, attachments, choose a suitable machine model. See the parameters, loading diagrams and the overall size of the machine. The overload is prohibited. Step 2. Install the attachment onto the end of the boom, make sure all the nuts are screwed tightly and the oil pipes well connecting without leaking. Step 3.Check all the functions to make sure all of them can move smoothly without abnormal sounds. Step 4.The other requirement please fellow the introductions.